AIS develops time saving and innovative hinged module solution

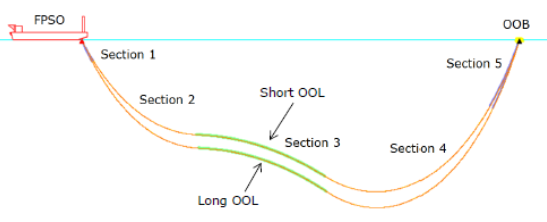

To meet the Jubilee Turret Remediation project’s demanding requirements, AIS developed a hinged module solution that connected the vessel via a series of floating cargo hoses and OOLs (Oil Offloading Lines). As a result, the module minimised installation time and simplified the removal of the counterweights following deployment.

The highlights

600m long mid-section

The solution had to be assembled horizontally on the welded pipe sections offshore during an S-Lay deployment. Each OOL pipe was suspended between the FPSO and oil offloading buoy to form a W-shape.

30mT static loads

Both the counterweights and buoyancy modules needed to withstand significant static and dynamic external loads as they passed over the stinger rollers during deployment.

ROV recovery

The counterweights needed to be suitable for removal and recovery using an ROV within three months of deployment.

Two innovations help meet project requirements

AIS developed a new and innovative hinged module solution and a cost-effective high-density material (4000kg/m3+) to meet the project’s requirements. This solution was cast into the lower half of the modules. The buoyancy modules were fixed to the pipeline using an enhanced version of AIS’s patented Type 3 Compliant clamp, which has a reduced size and a simple installation method.

A robust testing and development programme

To ensure all the challenging geometric and installation requirements were achieved, AIS implemented a robust testing and development programme once the initial design had been approved.

The project was successfully installed in a very short and critical timeframe and there was no requirement to use expensive vessel extensions.

Share your protection challenge

Do you need to protect equipment in an extreme operating environment? Let us discuss how we can help.

Get in touch