Installations that have mobile generators installed, have a range of potential health and safety risks that need to be adequately addressed to ensure the safe operation of the plant and equipment. The potential risks include:

• Ensuring safety of personnel who are operating within the enclosure and who may be subject to burns and proximity of hot exhaust lines

• Ensuring the generator is adequately insulated to prevent heat and energy loss

• Reduce risk of excessive noise through acoustic insulation

Why install ContraFlex® jackets?

ContraFlex® Jackets are manufactured using high temperature insulation materials and fabrics that can withstand up to 1,100oC making them an ideal solution for mobile generators and CHP Plants.

The jackets are easy to remove, inspect and replace during maintenance compared to heavy metal box type insulation that has traditionally been installed on these applications. All jackets are bespoke and fit the equipment tightly to ensure maximum thermal protection which helps to reduce emissions and reduce operators fuel costs. We understand our OEM customers require a uniform design and product regardless of where the jacket is produced.

With manufacturing facilities in the UK, UAE, South Korea, Brazil and Kazakhstan, we guarantee to be cost effective. The Global OEM businesses we currently work with are assured of local service and support at each location in addition to benefitting from global cost-effectiveness and a uniform design.

The bespoke installation pads create a square profile, before being wrapped in PFP on the structures. Our jackets are held in place using a unique first-fit Velcro type fastening which enables quick and easy installation. It also enables future maintenance checks to be made without removing the entire covering.

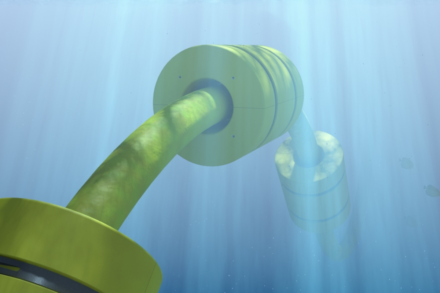

Where can ContraFlex® jackets be installed?

ContraFlex® jackets are effective across a wide range of gas and diesel engines to reduce the surface temperature of the equipment as well as the enclosure temperature. Reusable, the jackets can quickly and easily be removed whilst the generator is being maintained, reducing the time and cost of annual maintenance programmes. All our jackets are asbestos free, which means they are safe for operators and do not contain any harmful chemicals, so they are environmentally friendly too.

Some of the applications our jackets can be fitted to include…

• Exhaust pipework including bends and flanges

• Turbos

• Silencers

• Fuel pipework for heat conservation

Service and support

Our jackets are quick and easy to install, but our global network of trained installers can provide training or technical support if needed to your maintenance team.

All our jackets have a unique number, so should you require a replacement, you just need to give us the number and we can produce the correct jacket for you.