Our track record

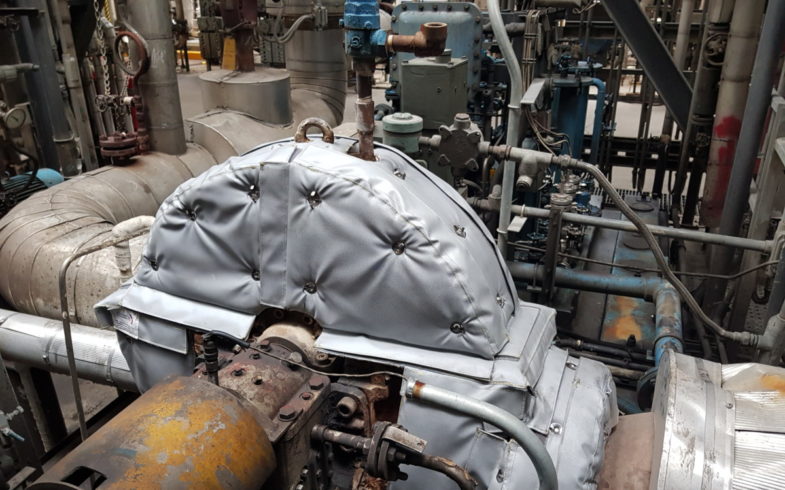

Typical applications include insulating intermediate pressure (IP) and high pressure (HP) turbine half joints, main boiler feed pumps (MBFP) in addition to ancillary equipment such as; stops, governors (Gov), valves and strainers including; vacuum tubes (VT) and idle control valves (ICV).

The table below illustrates our continual work with EDF power plants across the UK:

Date | EDF Station | Description | |

July 2016 | Hartlepool | Various jackets around the reactor, and maintenance on the centre line jacket | |

October 2016 | Heysham 2 | Maintenance on centre line jackets | |

February 2017 | Heysham 1 | HP and IP Stop and Gov valves | |

July 2017 | Dungeness B | Maintenance on centre line jackets | |

July 2017 | West Burton CCGT | Maintenance on centre line jackets | |

January 2018 | Hartlepool | MBFP live steam valve and suc-tion stage, plus various jackets around the reactor | |

May 2018 | Heysham 2 | Maintenance on centre line jackets | |

September 2018 | Dungeness B | Maintenance on centre line jackets | |

September 2018 | Torness | Replace IP top and ½ joints | |

March 2019 | Hinkley Point B | Replace IP top | |

June 2019 | Torness | Supply spare set of HP jackets for site | |

March 2020 | Hartlepool | Duplicate jackets on GT and ST (copy original OEM jackets) | |

March 2020 | Heysham 2- unit 8 | Repair / replace jackets on IP cylinder and Gov valves | |

April 2020 | West Burton CCGT unit 2 | Duplicate OEM GT and steam turbine (ST) jacket | |

September 2020 | West Burton CCGT unit 1 | Duplicate OEM GT and ST jackets | |

December 2020 | Heysham 1 unit 1 | Repair / replace jackets on IP stops and Gov valves | |

June 2021 | West Burton CCGT unit 3 | Duplicate OEM GT and ST jacket | |

June 2021 | Heysham 2-unit 7 | Repair / replace jackets on HP stops and Gov valves | |

December 2021 | Hartlepool unit 1 | Repair / replace jackets on HP and IP stops and Gov valves | |