From wastewater and sewage treatment works to breweries and other industrial plants, AIS has provided winterisation covers to a variety of facilities over the years.

The benefit of insulation covers is that they prevent equipment damage and leaks due to expansion that is caused by water in the system freezing during the winter months. Essentially, as the ice melts, leaks appear which are difficult for maintenance teams to repair.

Winter can be particularly damaging to facilities in cold climate regions such as Canada and Kazakhstan where essential equipment is located outdoors and exposed to the elements. This is where pipework, equipment, emergency assets, process lines, ducting and more need protection. Not only can the freezing conditions cause expensive repair works where equipment has completely failed, but it often results in downtime due to damaged pipelines.

Top winterisation tips

A well-prepared facility will be more likely to make it through the cold months unscathed. With this in mind, here are our top five winterisation considerations for your facility:

- Standing water and small diameter pipelines are susceptible to fast freezing

- If unprotected, valves and other moving parts may not operate correctly

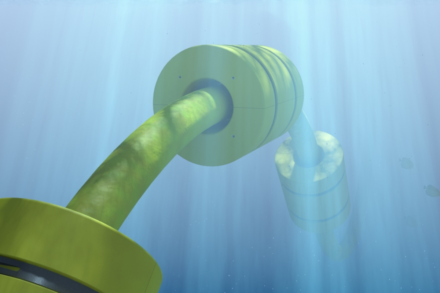

- Removable jackets protect pipelines and equipment against the cold and are simple to install

- Alternative metal box-type systems may take on water, which then causes corrosion under insulation (CUI) once thawed

- Winterisation campaigns need to be done before winter arrives!

Contraflex® benefits

Avoid expensive maintenance costs, damage to equipment, and downtime with our ContraFlex® jackets, made to a bespoke fit for the following benefits:

- ContraFlex® jackets protect equipment from direct contact with the harsh elements

- Our insulation jackets retain heat throughout the equipment

- The outer cover is a soft construction, making it less susceptible to damage during the removal and reinstallation. Many of our installation campaigns start with an inspection of boxes that have been removed and cannot be replaced.

- They can contain a self-regulating heat tracing element that runs through the inner face of the jacket. This prevents equipment from freezing by providing heat when temperature drops below a certain temperature.

Our removable jackets for pipelines can help you prepare before it's too late. Is your plant ready for winter? Protect it against the cold by contacting our expert team.