CRP Subsea has recently secured a substantial contract from a leading oil and gas original equipment manufacturer (OEM). Under this agreement CRP Subsea will supply cable protection for a deepwater subsea gas compression development, offshore Australia.

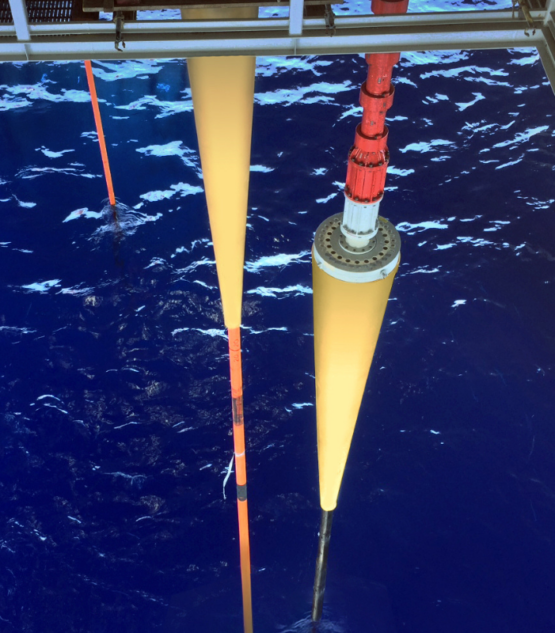

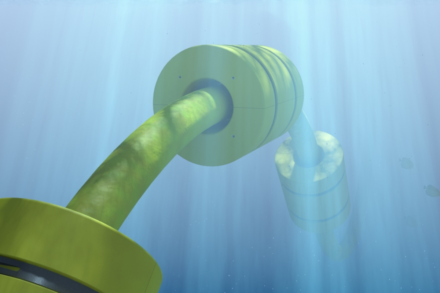

In this project, CRP Subsea are using their advanced engineering capabilities to tailor their bend stiffeners for two critical applications: subsea pump umbilicals (SPU) and subsea compressor umbilicals (SCU). They will provide optimal protection for the dynamic umbilicals, which are exposed to constant motion. The bend stiffeners will ensure long-term integrity of the dynamic umbilicals, protecting them from over bending at the termination points. Stopper clamps will also be engineered to be installed during laying, below where the bend stiffener will be positioned after hang-off. These purpose-built clamps serve the crucial role of preventing the bend stiffeners from descending to the seabed.

Ben Stubbens, Sales Team Manager at CRP Subsea states:

“We are delighted to have received this order from one of our valued existing customers. We believe that this order is a reflection of our impeccable reputation and outstanding track record of delivering bend stiffeners to the oil and gas market. In which we have maintained an exemplary in-service record, with no reported failures to date. We are honoured that our customer has placed their trust in us once again, reaffirming the confidence they have in our capabilities.”

The bend stiffeners and stopper clamps will be designed and manufactured at CRP Subsea’s leading-edge production facility in the North West of England. Project engineering works will begin imminently, with completion and delivery expected in the second half of next year.

Product information

A bend stiffener is a bend-limiting device used to protect flexible pipelines, umbilicals or cables. It does this in three ways; (1) They ensure the flexible pipe does not bend beyond the manufacturer's desired minimum bend radius (MBR) during the life of the project, in such a way as to optimise the fatigue performance of the flexible pipe. (2) They provide a suitable load path from the flexible pipe to the fixed structure. (3) Bend stiffeners reduce point loading at the termination point. We have an extensive track record in the supply of bend stiffeners, with zero failures.

For all your cable protection needs, contact our expert team to see how we can assist you with your latest project.