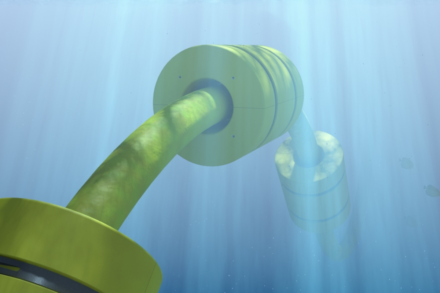

We are proud to announce the launch of a joint initiative with an international manufacturer of fluid control equipment.

Insulating fluid control equipment with ContraFlex® jackets does not only extend the lifespan of the equipment by protecting it from the external environment; it also significantly reduces energy loss and so reduces carbon footprint and delivers cost savings for the end user. ContraFlex® jackets are easy to install and refit, enabling quick installation and simple access for regular maintenance, which is an important requirement for fluid control equipment.

Through ongoing collaboration with our OEM partner, we addressed their concerns regarding the durability and heat conservation properties of traditional insulation solutions by offering a range of materials for the construction of ContraFlex® jackets. Our familiarity with facilities containing fluid control equipment enabled us to provide solutions for situations where the interface with adjoining equipment could compromise the fit, and therefore performance, of insulation jackets. Because of our understanding of the challenges of working in such facilities, we were also able to streamline the design of our jackets to simplify their installation even further without compromising their fit.

The library of ContraFlex® parts created through this initiative, together with our technical expertise and global manufacturing capability, ensures that we deliver accurately fitting and durable products, with a minimal lead time anywhere in the world.