ContraFlex® jacket insulation improves efficiency in Modular Power Plant

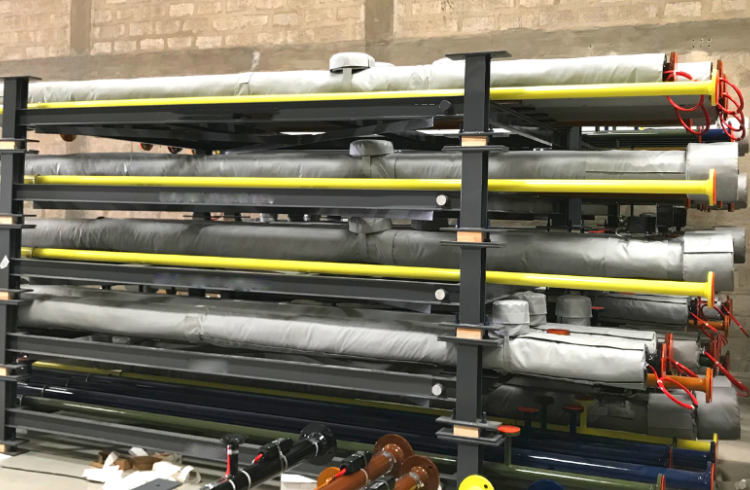

Our customer, a leader in mobile power generation required insulation for Heavy Fuel Oil (HFO) fuel lines which were mounted on pipe racks and trace heated. Their project was a new-build modular power plant in West Africa where multiple generators would be linked with fuel lines between them, all trace-heated and insulated.

The highlights

Recommendation

Increasing the length of the jacket from 1m to 3m, significantly reduced the installation time.

Tried and tested

Our system which has been tested against ISO 11507:2007 for exposure against UV and water to meet the customers requirements.

Unique design

All our jackets are unique to ensure we meet the specific requirements of your project and our jackets are a perfect fit.

The challenge

The insulation and trace heating were needed to ensure the HFO temperature remained above 98°C to avoid the tar-like fuel from solidifying. This will ensure effective and efficient power is available when needed.

With a design life of five years, any materials supplied for installation in the powerplant needed a proven capability to last that long insitu and be suitable for hot and humid environments with UV stability.

The pipe racks were 6m in length and the specification called for insulation in cladding type or jacket form with 50mm insulation.

Our solution

With a clearly defined specification, we demonstrated why our solution, would help our customer achieve their project objectives by:

• Recommending the installation of jackets 3m in length. Increasing the length of the jacket from 1m to 3m, significantly reduced the installation time

• Meeting the project requirement of UV resistance by recommending our ContraFlex® System which has been tested against ISO 11507:2007 for exposure against UV and water and is ideally suited for use in hot and humid environments

• Proven design life of ten years for this type of installation – exceeding the project requirement by 50%.

The results

All our jackets are bespoke to ensure we meet the specific requirements of your project and our jackets are a perfect fit – the full system required for this project was designed from 3D models prior to manufacture with only minor modifications required on site. With a 50% reduction in installation time using 3m lengths, there were significant cost and time savings for the project.

Whilst we initially worked with our customer through their Singapore office, our global capability provided us with the flexibility to manage and produce the jackets through our Dubai manufacturing facility to meet the needs of our customer.

Share your protection challenge

Do you need to protect equipment in an extreme operating environment? Let us discuss how we can help.

Get in touch