Turbines use “superheated steam” (steam that’s hotter than its vaporisation or boiling point at the absolute pressure where temperature is measured) which may cause health and safety risks if not insulated.

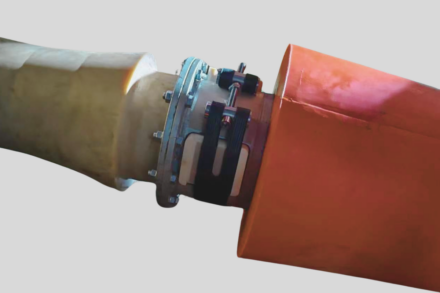

We design, manufacture and install ContraFlex® high temperature insulation jackets which operate up to 1,100°C through the use of specially selected infill materials and fabrics. Joints are staggered between the layers of insulation to provide minimal heat loss and maximum efficiency.

Typical applications include insulating intermediate pressure (IP) and high pressure (HP) turbine half joints, main boiler feed pumps (MBFP) in addition to ancillary equipment such as; stops, governors, valves and strainers including; emergency shutdown valves (ESV), vacuum tubes (VT) and idle control valves (ICV).

Benefits of using ContraFlex®

• Safely removable for inspection and maintenance – up to three times quicker than traditional methods

• Design ensures no hot spots, gaps or heat leakage

• Personnel protection and bespoke designs to fit your turbines

• Reduces noise and vibration

• Easy to repair or refit

• Jacket construction eliminates airborne fibres.

Cost savings

By reducing the removal, maintenance and reinstatement schedule from seven days using traditional insulation to three days with ContraFlex® jackets; reducing the outage time – for Hartlepool and Heysham 1, the system has provided over £5 million in cost savings.

“An all-round world class product and service, for over four years at EDF Hartlepool.”

Jason Young, Senior Project