Floating offshore wind farms are at the forefront of renewable energy innovation, harnessing the power of the wind in deep-sea environments. However, the success of these ventures hinges on overcoming unique challenges posed by the dynamic offshore setting. At the heart of these challenges are issues related to cable bending, heat dissipation, and the need for efficient manufacturing and installation processes.

With over four decades of experience in delivering buoyancy solutions to the offshore industry, we have utilised our expertise to tackle these challenges and developed a pioneering solution, NjordFloat. NjordFloat has been specifically designed for optimal performance on dynamic inter-array and export cables within floating offshore wind turbine (FOWT) systems.

Challenges in floating offshore wind farm buoyancy:

- Dynamic environment and cable stress: The relentless forces of the open sea generate enormous bending moments in the cables at potential rigid connection points. These unpredictable forces can compromise the structural integrity of the entire wind farm.

- Heat build-up: Transmitting electricity over long distances leads to significant heat generation in the cables. This heat build-up not only poses operational risks but also threatens the longevity of the infrastructure.

- Manufacturing and installation efficiency: With large-scale offshore wind farms spanning vast areas, the sheer quantity of modules required demands a solution that is fast to manufacture, easy to handle, and quick to install. Traditional methods often fall short in terms of efficiency and cost-effectiveness.

NjordFloat: Meeting the challenges with innovation

NjordFloat emerges as a pioneering solution designed specifically to address these challenges and pave the way for the future of floating offshore wind farms.

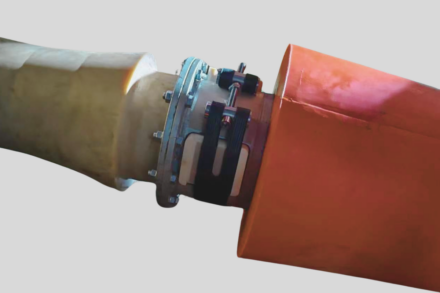

- Bend relief: NjordFloat provides essential bend relief at both ends of the product. This innovative design element helps mitigate the impact of dynamic forces, enhancing the durability and longevity of the infrastructure.

- Compliant clamping interface: This unique feature at either end of the NjordFloat ensures a secure yet flexible connection. It adapts to the dynamic forces of the offshore environment, reducing stress on the cables and associated components.

- Efficient heat dissipation: NjordFloat incorporates thermal channels and a clearance bore to encourage heat dissipation through convection. This not only prevents excessive heat build-up but also ensures the safe and efficient operation of the wind farm.

- Streamlined design: NjordFloat boasts a simple, well-thought-out design with a limited number of components. This simplicity not only makes it more cost-effective but also makes installation more straightforward and efficient.

- Rapid manufacturing expertise: using revolutionary manufacturing techniques and expertise, NjordFloat is able to meet the demand for large quantities of modules quickly and efficiently. This ensures that offshore wind farms can be deployed in a timely and cost-effective manner.

In the ever-evolving landscape of renewable energy, NjordFloat stands as a testament to creative thinking and pioneering innovation. By conquering the challenges of cable stress, heat dissipation, and manufacturing efficiency, NjordFloat not only makes floating offshore wind farms a more viable and sustainable energy solution but also paves the way for a brighter, greener future. With NjordFloat, we're one step closer to harnessing the full potential of offshore wind energy.

By Jonathan Fox, Engineering Team Manager at CRP Subsea.