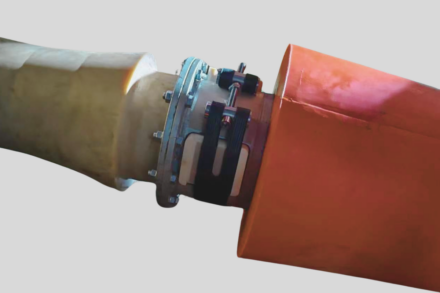

CRP Subsea’s distributed buoyancy modules will be supplied using their range of compliant market-leading internal clamp technology. The clamp used will depend on the specific application requirements, utilising a uniform circumferential clamping pressure will eliminate the risk of damage to the pipeline and ensure the modules maintain their position.

As well as buoyancy clamps CRP Subsea will engineer high capacity compliant tether clamps to be installed on the dynamic umbilical and anchored to the seabed keeping them in a desired position. At the topside dynamic bend stiffeners will be provided to protect the flexible pipes and umbilicals from fatigue and over bending at the termination point on the floating production, storage, and offloading (FPSO) vessel.

James Harrison, Key Account Manager at CRP Subsea states:

“We are thrilled to have been chosen by both the dynamic umbilical and flexible pipe suppliers on this prestigious project to supply a range of ancillary components to protect the critical assets from topside down to seabed. These contract awards help to reinforce our position as a global supplier and builds on our unrivalled track-record for buoyancy, clamping and cable protection solutions.”

All solutions will be designed and manufactured at CRP Subsea’s state-of-the-art production facility in the North West of England. Project engineering works will commence immediately, with completion and delivery mid-2023.

Distributed buoyancy modules (DBMs) are typically used between structures and a surface vessel or platform, providing uplift generated by a two-part buoyancy element and a clamp. CRP Subsea’s unique clamping solutions allow DBMs to be securely attached at any point along the length of a rigid or flexible pipeline or cable. From standardised clamps, where the technical demands are more benign, to the highest performing clamps the right solution can be provided.

Tether clamps keep a dynamic flexible pipe, umbilical or cable in a desired position. They are often used when flexibles are in close proximity and help avoid clashing. The tether clamp is installed on the flexible and is then connected to a seabed anchor or gravity base using a tether system.

Bend stiffeners are used to provide additional local stiffness to the umbilical or flowline, the conical shape provides gradual increases in the overall stiffness of the umbilical or flowline, in order to prevent over bending at the termination point.

Find more information about our buoyancy and cable protection solutions here