CRP Subsea has been awarded a sizable contract from a major engineering, procurement, construction and installation (EPCI) company. The contract entails the provision of vortex induced vibration (VIV) suppression strakes and buoyancy modules for an ultra-deepwater oil field development, located in the Gulf of Mexico, offshore US.

For this project, CRP Subsea will supply over 5 kilometres of Tri-Strakes® Lite, to provide VIV suppression to three steel catenary risers (SCRs) and two flowline jumpers. Anti-fouling will be applied to the Tri-Strakes® for use on specified sections of the risers to prevent marine growth. Each segment of the Tri-Strakes® Lite system is designed as a single, lightweight component, facilitating swift and straightforward pipe reel lay installation offshore. The system's design allows for efficient stacking during shipping, optimising space utilisation on the vessel.

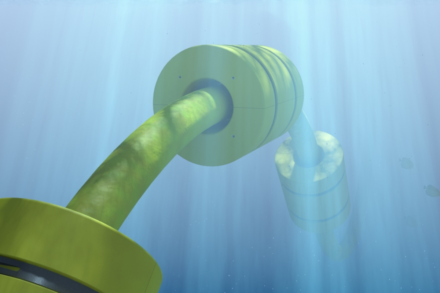

CRP Subsea’s innovative integral buoyancy modules will also be attached to the flowline jumpers. These modules will provide controlled buoyancy, reducing the bending moment on the structure. In addition, using an integral compliant clamping technology ensures a uniform clamping pressure, eliminating risk of damage to the flowline jumper.

Jaimin Parmar, Sales Engineer at CRP Subsea, states:

“We are thrilled to secure this contract, it is a testament to our commitment to innovation and excellence. The acknowledgment of both our Tri-Strakes® Lite and integral buoyancy modules underlines our dedication to delivering comprehensive and innovative subsea solutions. This success not only validates our technical expertise but also reinforces our position as a trusted and reliable partner.”

The Tri-Strakes® and integral buoyancy modules will be designed and manufactured and coated at CRP Subsea’s production facility in the North West of England. Project engineering works will begin imminently, with completion and delivery expected in the second half of this year.

Product information

Tri-Strakes® Lite is a high-quality Vortex Induced Vibration (VIV) suppression system consisting of overlapping and interlocking mouldings, with three-start helical strakes to provide an effective triangular or trapezoidal strake profile. Tri-Strakes® Lite has a temperature resistant up to 70°C/158°F. Each section of the system has been designed as a single, lightweight component, enabling quick and easy pre-install onshore or install offshore. The design permits the system to be stacked efficiently during shipping which also reduces space taken up on the vessel.

Integral buoyancy modules clamp directly to subsea pipelines providing buoyancy at specific locations. They combine the functions of the traditional clamp and buoyancy elements into one unit, so there is no need for a separate internal clamp assembly. As a result, they have fewer component parts so there is the added benefit of faster and more cost-effective installation. Integral buoyancy modules offer improved handleability using an innovative installation tool, consequently providing enhanced safety.

Contact our expert team today to discuss the Tri-Strakes® or buoyancy requirements for your latest project.